Theory or practice? Both! The idea of breaking through the classic separation of consulting and implementation did not happen by chance. After all, the increasingly complex processes in companies demand one thing above all else from logistics: A holistic approach and thus, holistic solutions. In our LILA CONSULT business unit, we advise companies on organizational structures, more efficient processes, and optimum logistics.

Success in your warehouses is one of the key competitive advantages that you can leverage through targeted investigation and optimization. Let's think together about what matters.

The Warehouse Excellence Competence Center focuses on the logistics processes within a logistics facility.

For each logistical stage, or rather goods receipt, picking, and loading, different solutions are available, from "manual to fully automated". One of the key questions in this Competence Center is the identification of the "ideal" solution alternative against the background of all of your specific influencing factors, such as: personnel access, area, budget, ROI expectation, maturity level of qualification, dynamic requirements, and volume.

The concept of supply chain management has long been considered an integral part of our everyday usage. We believe that you should not only look at your supply chains but at your entire supply network. Dive into the world of Supply Network Excellence with us and sharpen your focus.

From our point of view, the networking of various supply chains and a higher level of transparency are the keys to success. In the Supply Network Excellence Competency Center, the focus is on linking various supply chains and the resulting supply network.

Where do you need logistics facilities?

All these are typical issues in the Supply Network Excellence Competence Center.

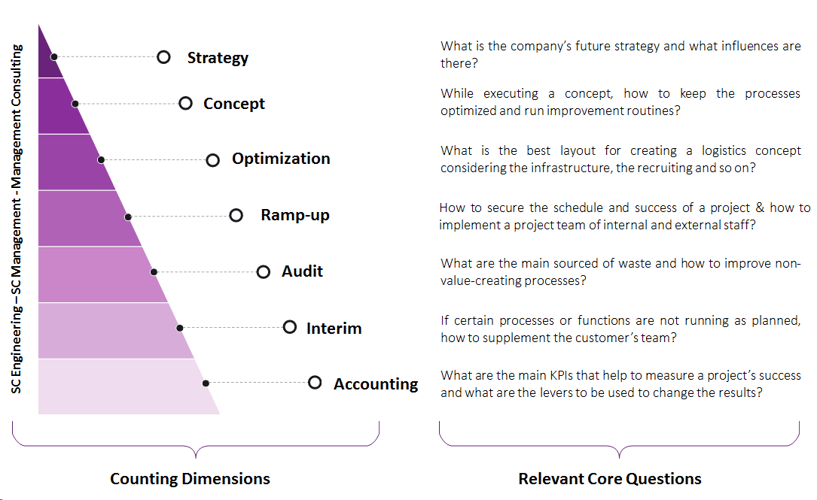

Below is an excerpt from our consulting approaches. These are customized and used in the respective context. The best result always comes from the right mix of consulting approaches.

Control Tower

The CONTROL TOWER team from Lila Logistik manages and controls the supply chain from collection at the supplier, through the plants and/or logistics centers, to the customer. All communication, as well as tracking and control, is done via a web platform. System-supported, transparent supply chain event management provides real-time notification of missed deadlines or other disruptions. The control tower acts as a counseling center during, for example, strikes or thunderstorms, a traffic monitor, and takes over escalation management.

Interim Services

INTERIM SERVICES involves targeted temporary and specialist temporary assignments by experienced Lila Logistik employees in customer companies. Our main focus is on supporting our customers in a logistical start-up phase. Whether it's the relocation or reopening of logistics service centers, the startup team supports you and your ideas. Both employees and their qualifications can be chosen freely.

Process and Quality Management

Quality is a critical success factor. Customer Satisfaction is an absolute must. Establishing and maintaining a sustainable quality management system that is focused on continuous process improvement ensures this. We, as Lila Consult, advise you in this respect professionally and organizationally in the conceptual design and operational implementation.

Supply Chain Security

SUPPLY CHAIN SECURITY: Following the terrorist attacks of September 11, the World Customs Organization has set standards to safeguard and facilitate world trade. The European Community integrated the safety provisions into the Community Customs Code and created the status of Authorized Economic Operator (AEO). Since 29.04.2010, the new EU Regulation No. 300/2008, which states that only air freight with the status "safe" may be sent is in effect. This eliminates the previous regulation for recognition as a "KNOWN SHIPPER" and "REGULATED EMPLOYER" by other companies in the supply chain. The approval is now carried out exclusively by auditing by the German FAA.

Logistics Cockpit

The basis for every optimization is current measurement results. Our LOGISTICS COCKPIT meets this idea. By generating process models and transforming them into process time specifications (based on REFA, MTM, Benchmark) and process costs, a structured logistics productivity and cost management system is implemented for the personnel and for the material handling equipment used.

Material Flow Planning

MATERIAL FLOW PLANNING, in short, deals with the planning, optimization and realization of material flow systems. With the support of our material flow planning, you can realize cost reduction potential, expect short implementation times, set the quality of new processes from the start, and minimize your project and start-up risk.

Transport and Network Optimization

The basis for new approaches in TRANSPORT OPTIMIZATION is the consideration of procurement and distribution flows. In the first step, a potential analysis evaluates transport prices, bundling/steering effects, and inventory reductions. In the concept phase, new network components, control functions, and processes are defined and advertised on the market.

Simulation

SIMULATION brings an existing logistics plan to life. Bottlenecks and confounding factors can be detected and eliminated in advance. The simulation technology used protects our customers from the start of new projects and processes by quickly checking different variants and scenarios. That is why it is cheaper than conventional planning, especially for large projects. In the long term, there are also enormous time savings and low adaptation costs for planning changes.

LDL Management

The LDL MANAGEMENT supports our customers in all necessary steps from the preparation and analysis of the necessary planning fundamentals, the preparation of the specifications, and development of a transparent decision template, up to the controllable integration of the logistics service provider into internal and external processes. Even with information on the contract and useful expertise on what information you need in what form, in order to achieve an optimal comparability of offers, we are at your disposal.

Logistics Audit

Within the scope of a LOGISTICS AUDIT we analyze your intra- and production logistics depending on the task. Using process analyses and benchmark studies, optimization potentials and paths for implementation and realization are shown.

Outsourcing Strategy

By analyzing and transparently presenting your cost, quality, and performance situation and taking into account medium-term corporate planning, we consider all the crucial criteria for a successful OUTSOURCING STRATEGY across all phases: From a make-or-buy analysis to tendering to implementation.

Supply Chain Audit

As part of a SUPPLY CHAIN AUDIT, we analyze your procurement, production and/or distribution logistics depending on the task. Using process analyses and benchmark studies, optimization potentials and paths for implementation and realization are shown.

Inventory Optimization

From our point of view, excellent INVENTORY OPTIMIZATION has the task of ensuring a short retention period of finished products. Throughput times that are oriented to the market and customer requirements must be defined in the production process and the finished stock must be adapted accordingly. In addition, seasonal and market-specific sales changes and trends should be recognized reliably and in good time. High product availability combined with minimized capital commitment must always be guaranteed. To produce as promptly as possible at the customer's desired delivery date and to ensure consistently high material availability with the shortest possible set-up times are crucial. The maxim of waste in production should be avoided in order to achieve optimal productivity.

Strategic Supplier Integration

STRATEGIC SUPPLIER INTEGRATION means ensuring a highly flexible supply of our own production. And despite increasing product complexity and variant diversity through suitable supply structures to keep capital low. Being able to respond early to impending supply bottlenecks through suitable logistics management is vital.

Supplier Qualification

We support all matters concerning SUPPLIER QUALIFICATION. When selecting suppliers, it is important to look at the price and the quality, but above all to check your own fields of interest and business models with those of the potential suppliers for matches. In order to achieve the strategic purchasing goals through planned measures and defined procedures, the existing supplier portfolio must be regularly determined for the expected business development, its fields, goals, and contents. Underfunding and suitable remedial actions must also be defined. For this purpose, suitable key figures for the sustainable regulation and adjustment of the delivery performance must be developed, introduced, and monitored in coordination with the company's own goals. Auditing procedures help to capture and evaluate the respective topic in a situation-related and target-oriented manner and jointly develop and implement optimal handling and replenishment strategies for the entire supply chain. We have to accept that suppliers - like products - have a life cycle and therefore need to be replaced at certain times.

Do you have any questions left? We sure hope so! Why don't you contact us:

Müller - Die lila Logistik SE

Ferdinand-Porsche-Str. 6

74354 Besigheim

Germany