"Everything will be different in the future; nobody knows what to expect". It's a statement that everyone knows, but what's behind it? Will the way we interact really change fundamentally? Is it really possible to estimate future developments? Let's take a look together at how digitalization is already influencing value chains today and what can be derived from it for the future.

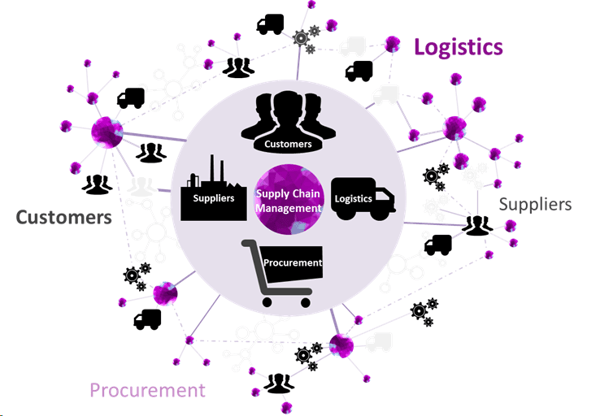

The classic, single-organization logistics in the form of transportation, handling and warehousing services has evolved into modern, cross-company supply chain management. Increasing demands from customers, employees, and partners require the entire value-added process to be more reliable and efficient. Instead of a sum of individual options, an overall optimum of the value chain is sought, in which processes are implemented as seamlessly as possible from the supplier to the end customer (i.e. across all procurement and sales stages). As a result, individual companies no longer compete with each other but rather the performance of their entire network competes with other networks. Supply chain management enables companies to unlock cross-network potential for success by developing, designing, managing, and realizing effective and efficient flows of goods, money, and information. If you want to make the best possible use of this potential, digitalization plays a crucial role.

In the era of Industry 4.0 and digital transformation, technologies such as big data, the Internet of Things, 3D printing, or augmented reality have emerged. They promote the emergence of new business models, the digitalization of products and services, and enable the integration and synchronization of the activities of all actors in the value chain. The question as to whether Supply Chain 4.0 is science fiction can be answered quickly: The mentioned technologies are part of our current working world. A survey conducted by management consultancy PWC in 2016 showed that already one-third of companies surveyed in 2000 have started digitalizing their value chain and that 72 percent of companies will start doing so within the next five years. Why almost every company wants to invest in this area long term is obvious. Many economic advantages are expected: Scientists forecast a possible increase in efficiency of 4.1 percent and an increase in revenue by 2.9 percent every following year. Digitalization has great significance for the future existence of your company. We show you what the concrete possibilities of digitalization along the supply chain look like and what opportunities arise for your business.

The supply chain is full of digital possibilities. Much is already present and some still lie in the future. Not every idea that we will present below will be suitable for your business or be translated one-to-one. However, they are a good opportunity to question your supply chain in terms of the potential use of digital technologies.

This is just a sampling of the ways you can make planning and execution of supply chain activities more efficient. Only when the systems are not only used individually, but networked via a platform, can their entire potential be exploited.

Wrong demand forecasts or missing blanks endanger the supply chain process, as a large number of activities are usually built on each other. In order to solve problems quickly and to minimize consequences, information exchange is extremely important. By integrating internal and external data, digital platforms form a central control and monitoring entity for all actors in the supply chain - from pickup at the supplier to delivery to the customer. For example, all communication, tracking, and control can be done via a cloud platform. This combines several systems so that you always have an overview of all processes along the value chain in the case of abnormalities. You'll be informed in real time and can intervene promptly via escalation management. Implementing a platform requires both technological understanding and human skills. Once the integrated platform is up and running, it reduces the overall planning effort enormously and generates significant added value for the user. When building a platform, you are supported by our experts.

The digitalization of our working world redefines purchasing and procurement processes. The demands placed on employees for IT know-how are increasing, new procurement categories are emerging, and the benefit promises of procurement functions are changing. Foresighted market and supplier analyses, co-creation (i.e. the involvement of suppliers in product development), and electronic contracts open up new possibilities for purchasing and increase its importance for the strategic success of your company. However, it is not enough to oil the gears within your own company. It is crucial that you also involve upstream and downstream stakeholders, thereby increasing process efficiency along the entire value chain.

Do you think that sounds like science fiction? It's not. It's already a reality. The fact that the innovative technologies are not so widespread is only due to high development and production costs. Once they drop, nothing stands in the way of broad-based application.

Spare parts management is a tiresome topic. In many industries, around half of all orders consist of one-off requests for spare parts. Demand is erratic and therefore hard to predict. This leads to large inventories, especially as spare parts have to be legally deliverable for up to 30 years. Keeping all C-parts in a second-rate, lower cost warehouse is not an up-to-date solution. Rely on 3D technology instead. Laborious pre-production and long-term storage are no longer necessary; you can re-produce the spare parts requested by your customers within minutes. All you need is some technical skills, a 3D printer, appropriate software, blueprints of spare parts, and the material needed for production. Investment costs are quickly recouped by the associated storage fees and the reduced goods handling.

The shortage of skilled workers and the increasing volume of transport on the roads make it increasingly difficult for companies to satisfy all customer requests. In the warehouse, therefore, autonomous means of transport will continue to gain in importance. Digitalization will also create new transport options in road traffic. The first autonomously driving trucks are on the way. Companies like Daimler, Tesla, and some IT companies have already developed other technologies for autonomous transport solutions. First and foremost, however, it is important to create both the legal basis for autonomous driving and the infrastructure for the most current-powered means of transport of the future. In the long run, the economy cannot run without new technology; the implementation of these technologies into daily business is only a matter of time.

When implementing a smart supply chain, you should, in our experience, consider the following success factors:

You have any questions? We're looking forward to hearing from you.

This post won't teach you what the value chain of the future looks like. The topic is too complex for that. But it shows that fundamental changes are coming to us in the not-so-distant future. If you want to find out how to use digitalization and innovative technologies in your company, we are here to help.

Müller - Die lila Logistik SE

Ferdinand-Porsche-Str. 6

74354 Besigheim

Germany