Supply Chain Management gives you the opportunity to become better. The reason: Work within a firm is organized into functional processes- that is to say, department-oriented, whose goals can conflict with the fulfillment of customer orders. This means that friction losses are inevitable. Supply Chain Management bridges this gap. It refers to the holistic process-oriented method for the fulfillment of a customer order, from receipt to delivery, all necessary activities and intermediate steps included. That saves you time and money. You're committed to implementing supply chain management that identifies and eliminates potential weaknesses. And we're happy to help with that.

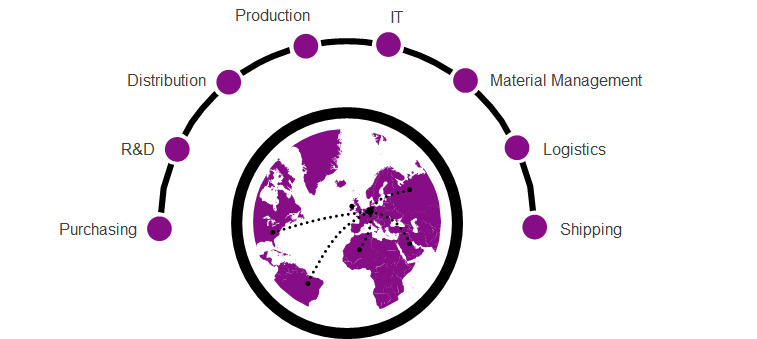

When you make Supply Chain Management a focus, you are switching from a function-oriented to a process-oriented order fulfillment process. For our customers, we build an order fulfillment process with the highest possible degree of standardization, geared towards adding value to your company. The key to success is to make sure all affected areas are involved when defining the fulfillment process. From our point of view, these include:

With a common focus on a cross-functional process, you avoid conflicting goals between these areas. Only when all areas align their activities with the cross-functional process can you leverage room for improvement and achieve sustainable competitive advantages.

The integration of all areas into the supply chain also allows:

In global markets, tough competition and crowding out principles are the rule. Effective and efficient supply chain management helps you assert yourself. We help you identify or eliminate possible deficits or cost drivers in your supply chain. Here are some examples:

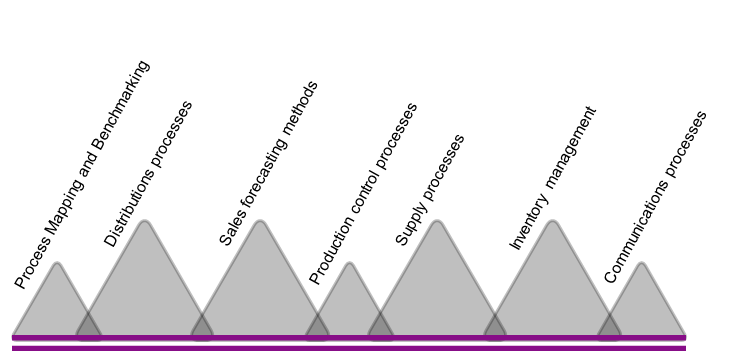

If you want to introduce supply chain management in your company, it's time to take a closer look. First and foremost, it's necessary to consider your previous Order Fulfillment Process (OFP) and its subprocesses. Basically, these include:

For each of our clients, we focus on every area in detail to make individual analysis areas supplemented by consequences of optimization for each.

For clarification purposes, here is an example for the area of Process Mapping. We have listed six individual analysis areas and the benefits of optimization for each, with respect to a willingness for change by employees and an estimation of effort for implementation.

Analysis Areas for Process Mapping |

Effects, Utilization, Opportunity |

| 1. Inclusion of all functional and procedural parts in the OFP | Visualization of organizational and procedural structures, dependencies, and vulnerabilities. |

| 2. Illustration of information processes, methodical, chronometric, and physical processes | Identification of optimization potentials (procedural/structural) |

| 3. Identification, grouping, and classification of process structures | Assessment of the current structure's effectiveness and efficiency within the frame of a SWOT analysis |

| 4. Analysis of existing indicators, their origin, and their relationships. | Development of an implementation strategy to create and efficient supply chain organization |

| 5. Illustration of organizational and hierarchal structures and processes in the OFP, including responsibilities and competencies | Identification of process disturbances and breaks |

| 6. Interface management | Support of change management |

You can find out how to update your supply chain by downloading our white paper on this page.

If you'd like to find out more about the stages of a supply chain project and methodical approaches, we'd love to share our knowledge with you. Please reach out to using our Contact page.

Müller - Die lila Logistik SE

Ferdinand-Porsche-Str. 6

74354 Besigheim

Germany