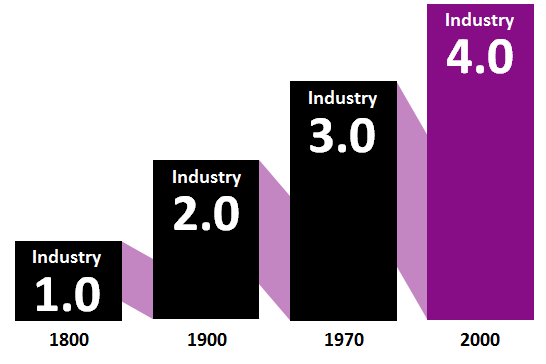

4.0 is in. When it comes to digitization, it appears in almost every context. Everywhere you hear Industry 4.0, HR 4.0, Marketing 4.0, Sales 4.0. Why? And is there more to it than a trend? The origin of the 4.0 rhetoric was an endeavor to secure the future of Germany as a business location through the comprehensive digitization of industrial production. The term Industry 4.0 proclaimed the fourth Industrial Revolution, which, like its predecessors, will bring profound economic and social changes.

The first Industrial Revolution in the 18th century triggered water and steam powered machines and plants. A century later, the switch to electric drive technology enabled automated assembly line production, and thus began the second Industrial Revolution. Production goods could be mass produced at significantly lower prices. The foundation for capitalism was laid and brought prosperity across society. After another 100 years, in the last quarter of the 20th century, electronic information processing started the third Industrial Revolution. This allows for more complex automation solutions and has lasted over 40 years as the acceleration factor continued to increase. The progressive merger of production and information technology is now creating new possibilities for interconnectivity. The latest fourth Industrial Revolution is aimed at the automated exchange of data along the entire value chain and thus at the highly efficient control of the cooperation of machines, systems, and people via algorithms. In connection with this would be a possible reversal from mass production towards individually tailored goods and services for the user. The expectations in these technologies are high, and whether the revolution fulfills its promises will only be seen in the coming decades.

As a forward-looking company, we, at Müller - Die lila Logistik, are keenly aware of this topic. Whether revolutionary or evolutionary, digitization will change supply chain management. All actors who are now partly independent of each other in the complex supply chain will become networked, collaborate together at a faster pace, and exchange information in real time via a common infrastructure. The resulting fall in fault tolerances will require parallel automated quality management, with real time, comprehensive KPI evaluation real time. All in all, the supply chain will process data volumes that were unthinkable just a few years ago. It's a challenge that is immense, but in our view, just as promising.

Although the development of ERP systems that transform heaps of data into actionable data is still currently in its infancy, forecasts assume that they will reduce the logistics costs of SMEs by around 10 percent in just a few years. Through supply chain management, which provides the optimal overview as the interface of all material and information flows and controlling the entire logistics chain via Fourth Party Logistics Service Providers, the accelerated flow of information will not only contribute to cost optimization, but also create transparency and comparability. Benchmark analyses would become real-time modules in day-to-day business, and modern, information-enabled knowledge management systems will increase efficiency across departments, locations, or companies, and reduce waste sites, such as construction sites.

Ultimately, the only question left is how quickly we are ready to accept this change and to contribute. We cannot prevent change, and we will have to learn that data is not lying, that markets and business models are accelerating rapidly, and that digitization is not simply updating the past, but brings something new along (e.g. machine learning and artificial intelligence).

The idea and research of artificial intelligence (AI) has been around since the mid-1950s. AI is an opportunity for humans but also threatens human labor. In many areas it can and will replace human interaction. Supply chain management could revolutionize it, as sales and revenue forecasting capabilities increase significantly. By intelligently matching an infinite amount of data, one day, perhaps, one can reliably predict whether and how many chocolate Santas will sell in stable weather conditions in South Africa. The reality is surprisingly close. With the right methodological competence, it is in fact possible to write algorithms that can predict tomorrow's trends, especially in the B2C segment and for low value-added logistics processes, such as in C-parts management. AI will make a lot easier, far more accurate, and more cost-efficient.

Initially, AI is expected to be used in logistical routine processes. AI strives for perfection and is faster and safer in its analyses and decisions compared to humans. These include, for example, the calculation of demand patterns, the determination of load times, and the selection of cost-efficient freight routes or haulage companies. In the long run, optimization and planning processes by AI will be fast, reliable, and real-time.

Research and business will drive development. It is already foreseeable that billions will be invested worldwide in the next few years. Whether or not and how quickly this will actually generate income will be shown by the pioneers.

In our book, „VORDENKEN“, Ulrich Sendler highlights the topic in the chapter, "A possible export hit made in Germany - Industry 4.0 as an opportunity." You are welcome to download the file!

As an implementation-oriented consulting firm, we are curious to see how fast digitization and the use of artificial intelligence in the supply chain will progress. Within this background, we deal daily with changes in the market. Therefore, it's important for us to maintain a strong network and to venture into the future.

In Lila Consulting's own competence centers, it is very important that we constantly try new things and also recognize the potential for when it makes sense to use new technologies. However, it also needs to be recognized when established technologies offer a greater advantage. However, it's just as important to us to find out what you think and expect from your company in the long term. Get in touch with us; we look forward to the discourse with you.

Müller - Die lila Logistik SE

Ferdinand-Porsche-Str. 6

74354 Besigheim

Germany